E: enquiry@technicut.co.uk

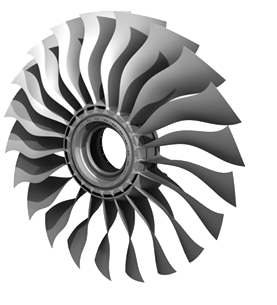

Recent market developments have introduced carbon fibre fan blade technology with the subsequent need for highly complex titanium shrouds or leading edges. Technicut has been at the forefront of this component evolution and has developed optimised tooling solutions for the production of these critical parts.

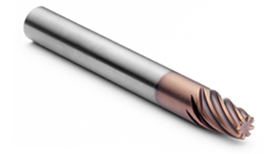

Titanium roughing endmill optimised for heavy duty machining and high metal removal.

.jpg)

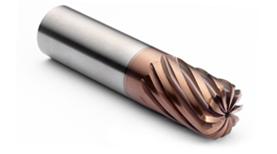

Titanium specific Ball Nose ripper endmill for blade profiling and increased metal removal from using conventional plain edge ball nose end mills.

.jpg)

High precision ball nose endmills with optimised TX coating boasting a high resistance to heat and adhesion when cutting HTSA materials.

Specifically designed for contoured surfaces. This tool enables high metal removal rates with good surface finish and quality by tilting the tool to create and elliptical form onto the surface.

Technicut's high-feed solid carbide roughing and finishing endmills give you the optimal solution for pocketing, helical interpolation and contouring applications and deliver up to three times faster machining than conventional methods.

Optimised ball nose tooling utilising high flute density technology to facilitate elevated feed rates to reduce cycle times with no compromise on surface finish.

Highly accurate taper ball nose range for blade roughing, semi-finish and finishing with an unrivalled surface finish.