E: enquiry@technicut.co.uk

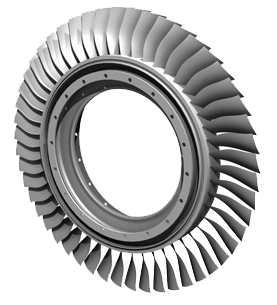

Technicut has developed market leading tooling solutions and innovative application strategies for the roughing, semi-finish and finish machining of all integrally bladed rotors.

Tooling and strategies for the most complex blade and blisk geometries, optimised for your chosen machining platform.

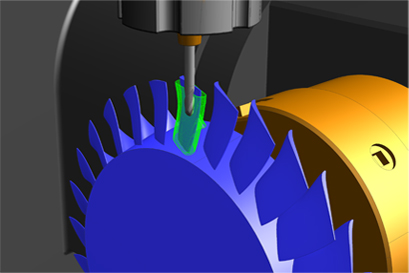

Our productivity solutions include:

Titanium roughing endmill optimised for blade slot milling and workpeice security.

Titanium roughing endmill optimised for 'near-net-shape' blade slot milling. X-tra long reach tooling available for challenging deep blade geometries..

Parallel or tapered titanium specific ball nose ripper endmill for blade profiling and hub/annulus slot roughing.

Near-net-shape titanium blade semi-rough profiling, minimising finishing time with greater effective cutting.

Technicut's Barrel Finisher allows greater effective cutting in both Nickel and Titanium, reducing extensive semi-finish & finishing operations.

Solutions for both Nickle and Titanium, Technicut's highly accurate taper ball nose range cater for blade and annulus/platform roughing, semi-finish and finishing.

Optimised ball nose tooling technology for rough slot milling nickel & titanium as well as solutions for roughing, semi-finish and finish blade scanning/profiling and hub work.